ERP for Chemical Industry

ERP systems can boost productivity and efficiencies for chemical manufacturing companies, plus enable them to operate compliantly and across borders with ease.

At ERP Research we provide independent advice and analysis for the best chemical ERP software, helping you find the best chemical manufacturing software, faster.

Top 10 ERP Systems for Chemicals

Learn everything you need to know about the best ERP solutions for chemical manufacturers in our detailed solution comparison report. We compare top chemical ERP software such as SAP, Microsoft, Oracle and more.

ERP for Chemical Industry

Small and medium sized (SME) chemical manufacturing firms need ERP systems which are cost effective, fast to implement and scalable.

Many manufacturing organizations have adopted ERP solutions such as these to handle their growth efficiently:

Infor CloudSuite Industrial (Syteline)

Infor CSI is a popular ERP solution for small and medium sized manufacturing companies in discrete and process manufacturing industries. See how Infor compares.

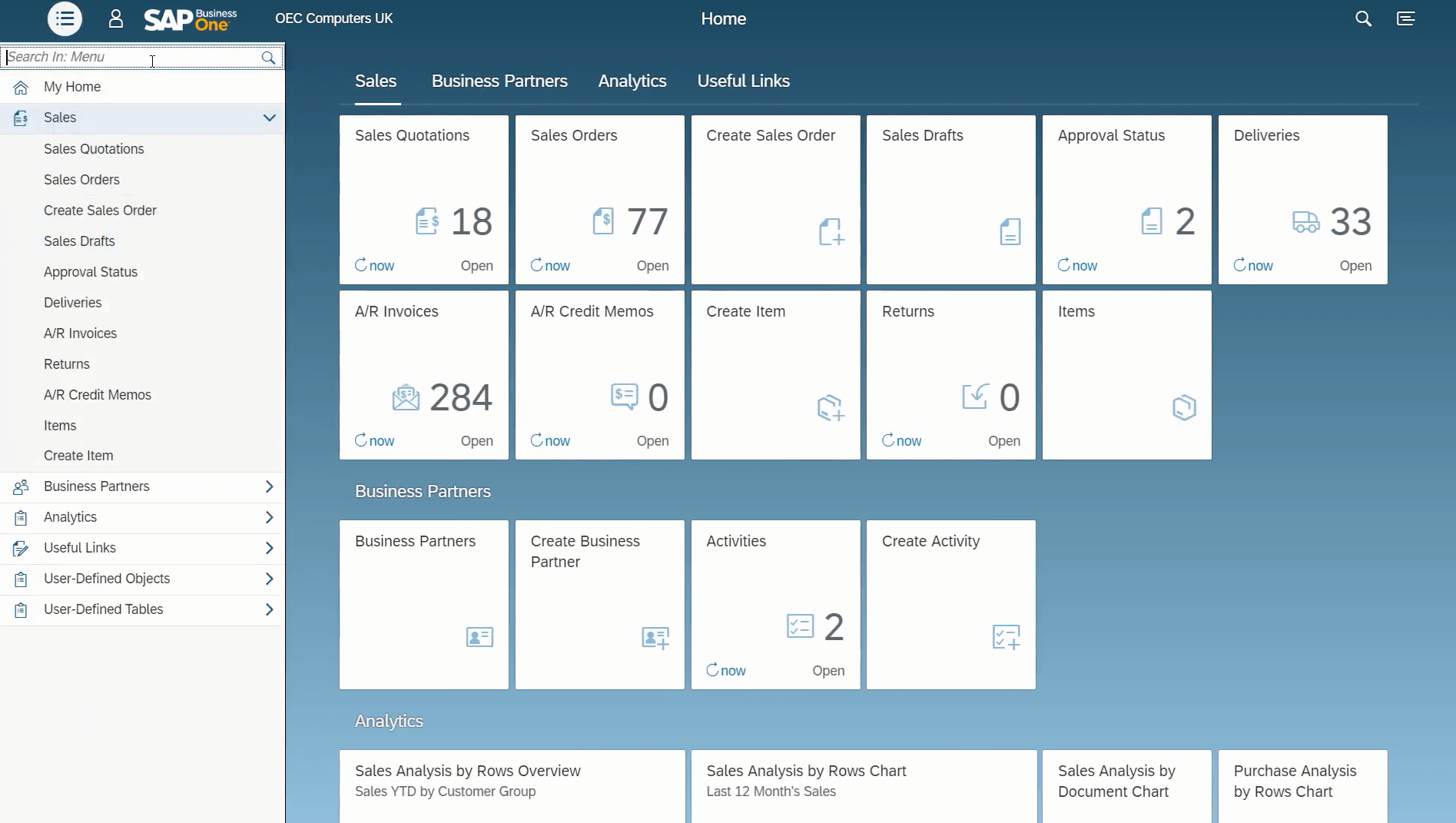

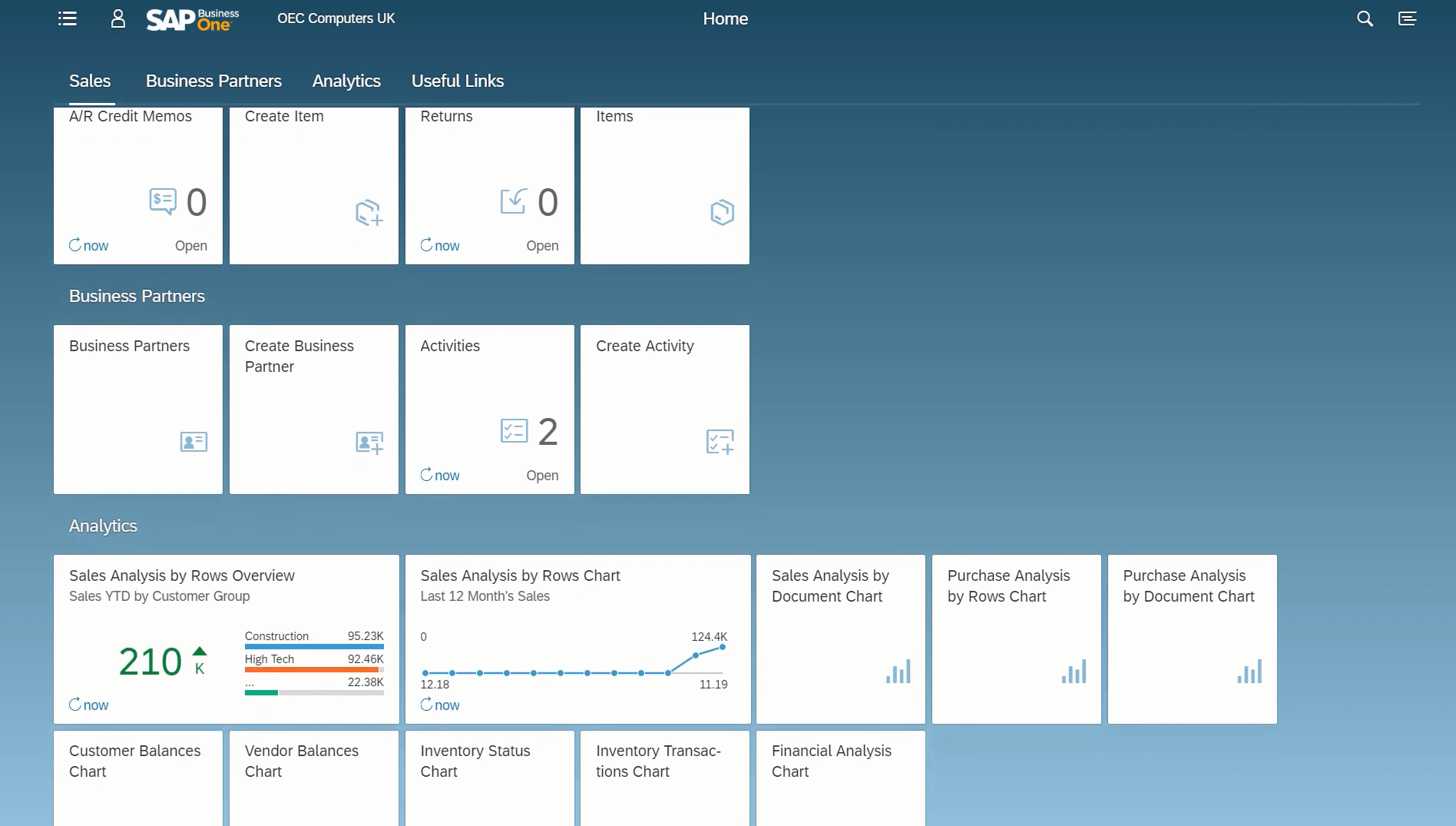

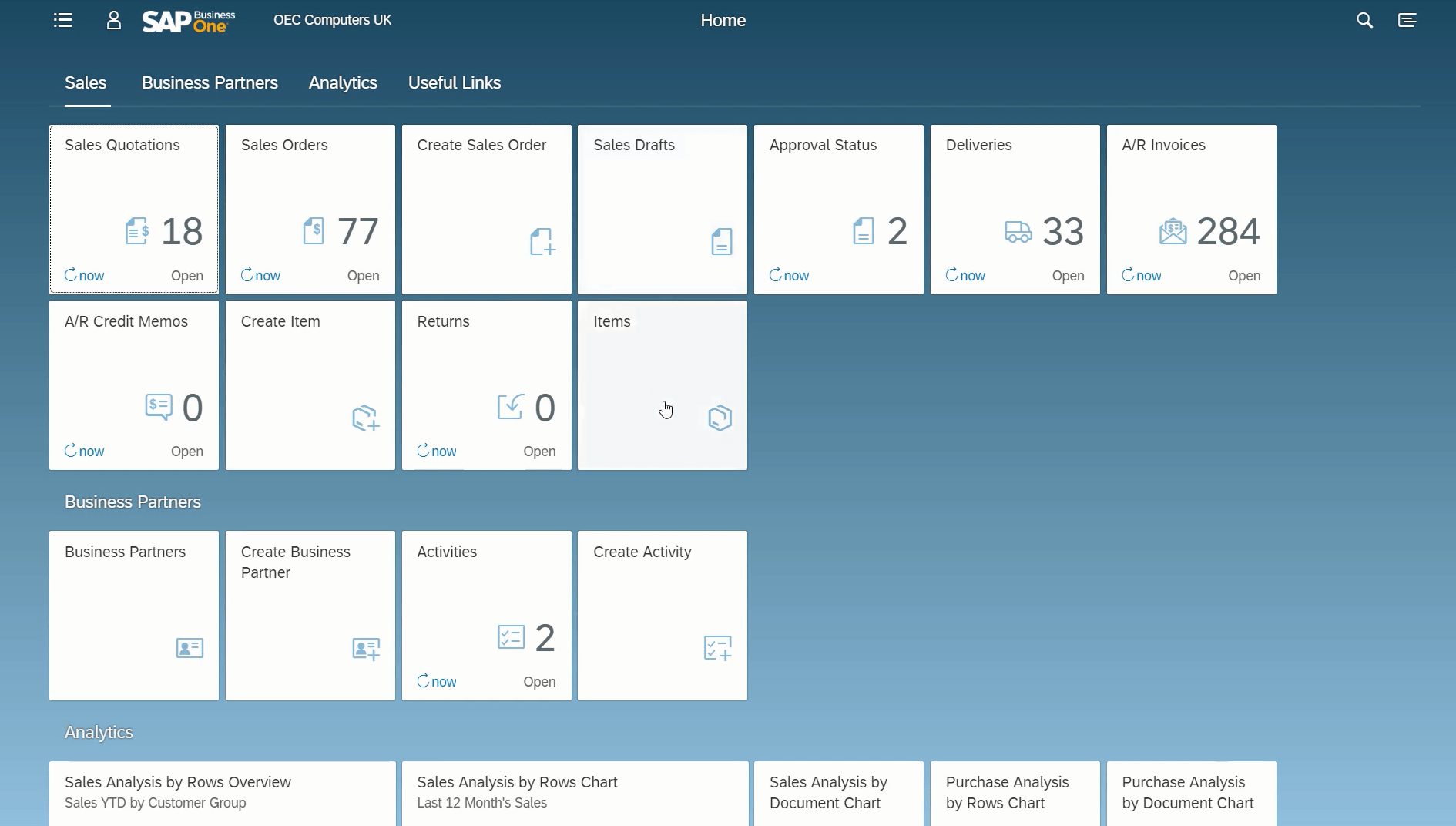

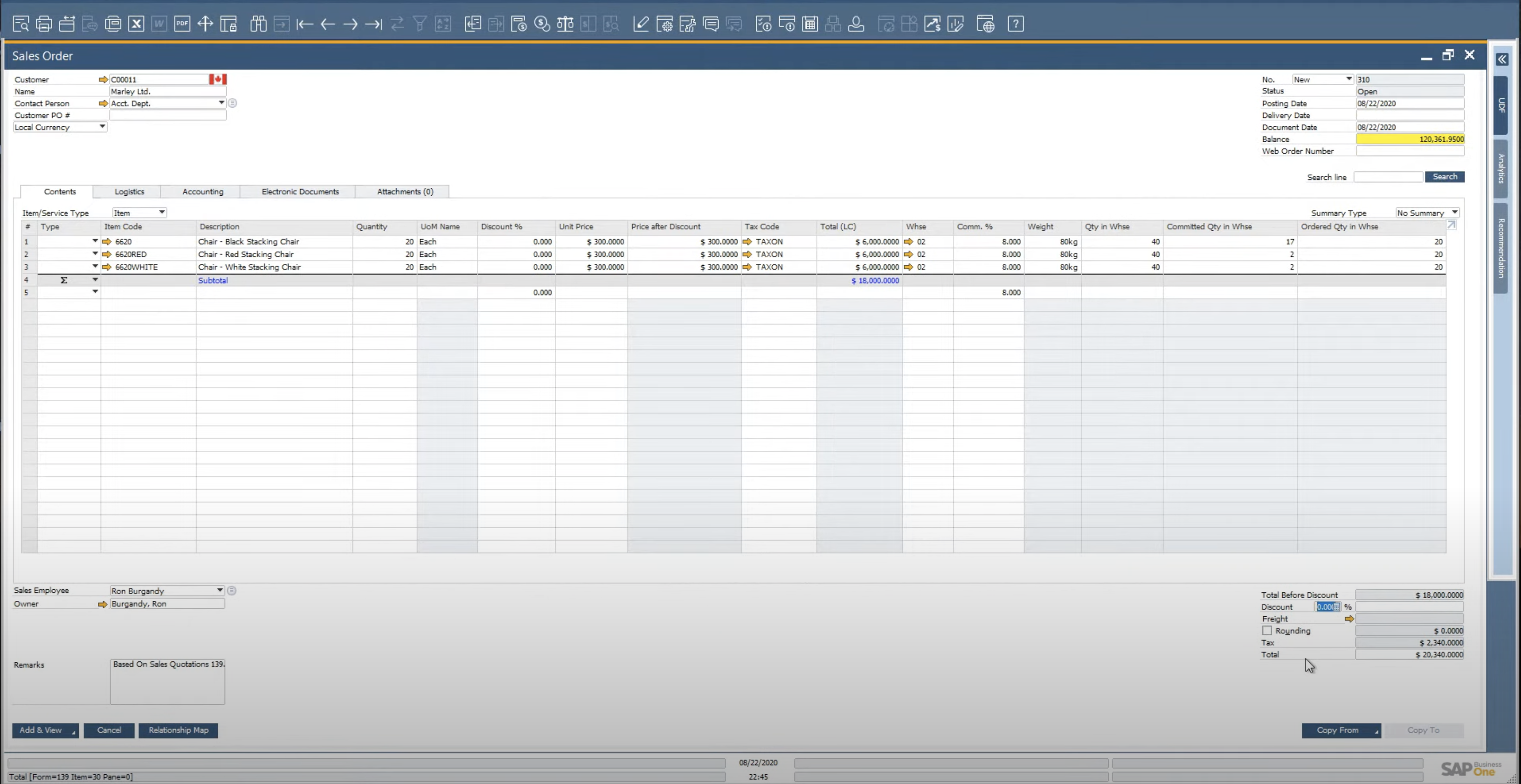

SAP Business One

SAP Business One has developed many manufacturing specific add-ons for various manufacturing sub-verticals including textiles, food and beverage production, making it a strong choice for small manufacturers.

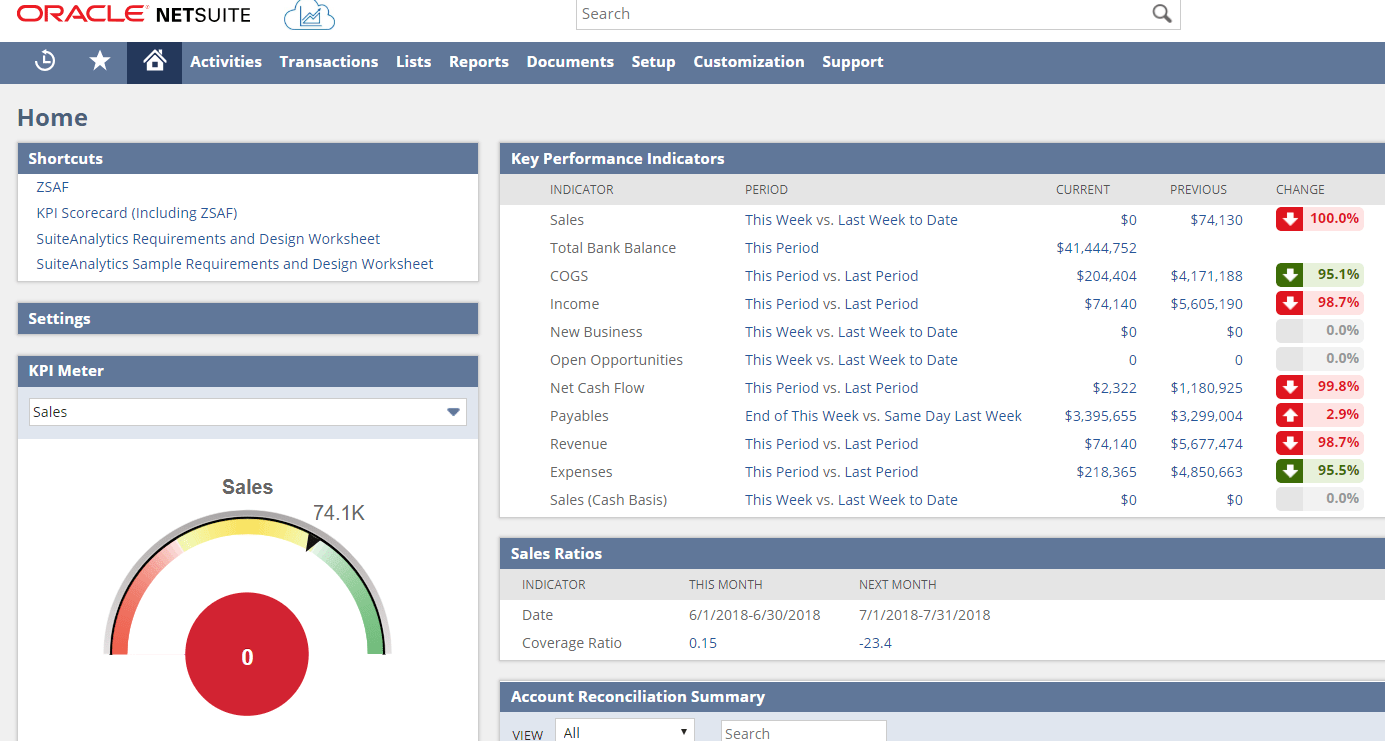

Oracle Netsuite

Netsuite has become a popular ERP system choice for small and medium manufacturers that are looking for a Cloud based ERP system to manage growth across sales, production, supply chain, inventory and financials.

Odoo

Odoo is an open source ERP platform which has been used by small and fast growing manufacturing organizations looking to unify their processes.

SAP Business ByDesign

SAP Business ByDesign is a Cloud ERP solution that serves as a stable solution with over 30 out of the box processes for manufacturing firms.

Microsoft Dynamics Business Central

Microsoft Dynamics 365 Business Central is used by SMB & SME manufacturers.

SYSPRO ERP

SYSPRO is a popular ERP solution for small business manufacturers in multiple industries, with a variety of process and discrete manufacturing capabilities.

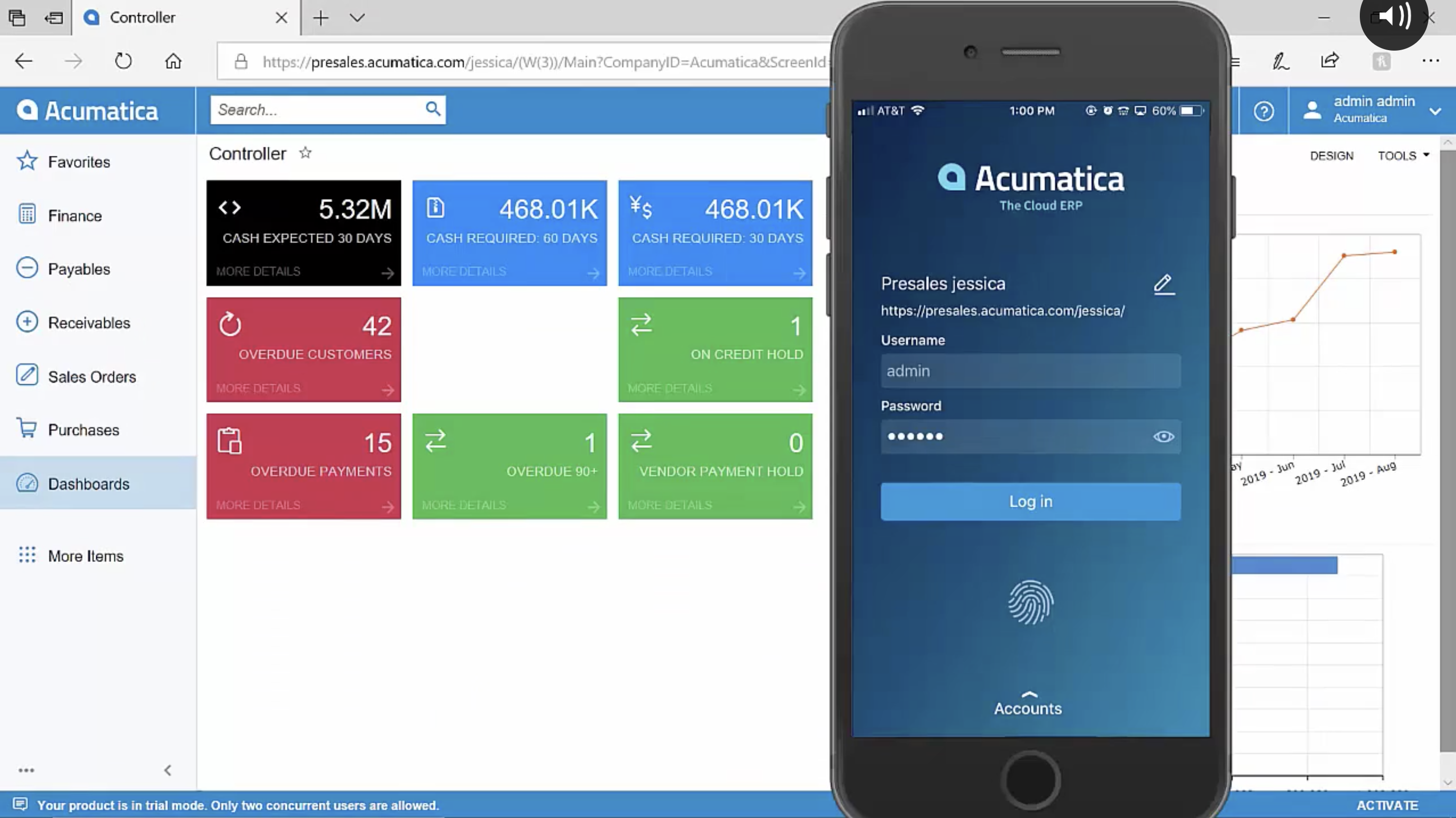

Acumatica

Acumatica is a powerful Cloud based ERP system which is used by SMB and small business manufacturers around the world and provides deep manufacturing ERP capabilities.

IFS Applications

IFS Applications is a strong ERP solution for manufacturers in the small and medium sized business space and is used by worldwide brands.

Top Chemicals ERP for Large Enterprises

What are some of the best ERP systems for large food and beverage manufacturers? See our highlighted best ERP software solutions for large manufacturing companies below:

SAP S/4 HANA

SAP S/4 HANA for many is the gold standard ERP solution for large manufacturers. It provides deep industry capabilities for manufacturing and offers the largest customer base of global manufacturing organizations.

Microsoft Dynamics 365

Microsoft Dynamics 365 has become extremely popular with manufacturing organizations that need a greater degree of flexibility in their ERP system. Microsoft has also heavily invested in AI & ML capabilities to improve automation and efficiencies.

Oracle ERP Cloud

Oracle ERP Cloud is a popular ERP solution for the food and beverage industry, particularly in food processing industries. ERP Cloud offers integrated functionality across large enterprises including supply chain, production, HCM, financials and more.

Cloud ERP for Chemicals Manufacturing

What are some of the best Cloud ERP systems for food and beverage manufacturers? See our highlighted best ERP software solutions for food manufacturing that are Cloud based:

SAP S/4 HANA

SAP S/4 HANA is one of the best Cloud ERP for manufacturing and is used by many manufacturing companies in the food, discrete, automotive and other manufacturing industries. This Cloud ERP solution is available in private or public Cloud deployments.

Microsoft Dynamics 365

Microsoft Dynamics 365 is a robust Cloud ERP for manufacturing system which comes in several editions built for small and large businesses alike. Dynamics is one of the best Cloud ERP for manufacturing, available in both private and public Cloud.

Oracle ERP Cloud

Oracle ERP Cloud is a popular ERP solution amongst manufacturers, particularly in process industries. ERP Cloud offers integrated functionality across large enterprises including supply chain, production, HCM, financials and more.

SAP Business ByDesign

SAP Business ByDesign is a fully SaaS Cloud ERP for manufacturing solution that serves as a stable solution with over 30 out of the box processes for manufacturing firms.

Oracle Netsuite

Netsuite has become a popular ERP system choice for small and medium manufacturers that are looking for a Cloud based ERP system to manage growth across sales, production, supply chain, inventory and financials.

Infor CloudSuite Industrial (Syteline)

Infor CSI is a popular Cloud ERP solution for small and medium sized manufacturing companies in discrete and process manufacturing industries. See how Infor compares.

SAP Business One

SAP Business One is a powerful business management software that can be utilized by chemical companies to streamline their operations and increase efficiency. Here are some ways chemical companies can use SAP Business One:

-

Inventory Management: Chemical companies can use SAP Business One to manage their inventory of chemicals, raw materials, and finished products. The software provides real-time inventory tracking, which helps companies optimize their inventory levels and avoid stockouts.

-

Quality Control: SAP Business One can help chemical companies manage their quality control processes by tracking quality control test results and identifying any issues with product quality.

-

Production Planning: Chemical companies can use SAP Business One to plan their production processes and optimize production schedules. This helps to minimize waste and reduce production costs.

-

Compliance Management: SAP Business One can assist chemical companies in managing compliance with regulatory requirements. The software can help companies maintain compliance with environmental, health, and safety regulations, and can also assist with managing compliance with industry-specific regulations.

-

Financial Management: SAP Business One provides chemical companies with comprehensive financial management capabilities, including accounting, budgeting, and financial reporting. This helps companies to track their financial performance and make informed decisions about their operations.

SAP Business One

SAP Business One is a powerful business management software that can be utilized by chemical companies to streamline their operations and increase efficiency. Here are some ways chemical companies can use SAP Business One:

-

Inventory Management: Chemical companies can use SAP Business One to manage their inventory of chemicals, raw materials, and finished products. The software provides real-time inventory tracking, which helps companies optimize their inventory levels and avoid stockouts.

-

Quality Control: SAP Business One can help chemical companies manage their quality control processes by tracking quality control test results and identifying any issues with product quality.

-

Production Planning: Chemical companies can use SAP Business One to plan their production processes and optimize production schedules. This helps to minimize waste and reduce production costs.

-

Compliance Management: SAP Business One can assist chemical companies in managing compliance with regulatory requirements. The software can help companies maintain compliance with environmental, health, and safety regulations, and can also assist with managing compliance with industry-specific regulations.

-

Financial Management: SAP Business One provides chemical companies with comprehensive financial management capabilities, including accounting, budgeting, and financial reporting. This helps companies to track their financial performance and make informed decisions about their operations.

NetSuite

NetSuite can be used as an ERP for chemicals by providing a comprehensive solution for managing various business processes such as manufacturing, inventory management, sales, purchasing, and finance.

Here are some ways NetSuite can be used specifically for chemical companies:

-

Batch Manufacturing: NetSuite's manufacturing module can handle the batch manufacturing process required in the chemical industry. It allows for tracking of raw materials and inventory, generating batch tickets, and managing production schedules.

-

Inventory Management: NetSuite's inventory management module provides a real-time view of inventory levels, tracks raw materials and finished goods, and automates inventory replenishment based on predefined levels.

-

Compliance: The chemical industry is highly regulated, and NetSuite helps with compliance by tracking batch and lot numbers, managing MSDS and SDS documents, and ensuring proper labeling.

-

Sales and Distribution: NetSuite's CRM module can help manage the sales process by tracking leads, opportunities, and quotes, and converting them into sales orders. It also enables sales forecasting and tracking of sales performance.

-

Purchasing: NetSuite's procurement module allows for the management of the purchasing process, including purchase orders, supplier management, and vendor performance tracking.

-

Financial Management: NetSuite's financial management module provides a comprehensive view of the company's financial health, including accounts payable and receivable, general ledger, and cash management.

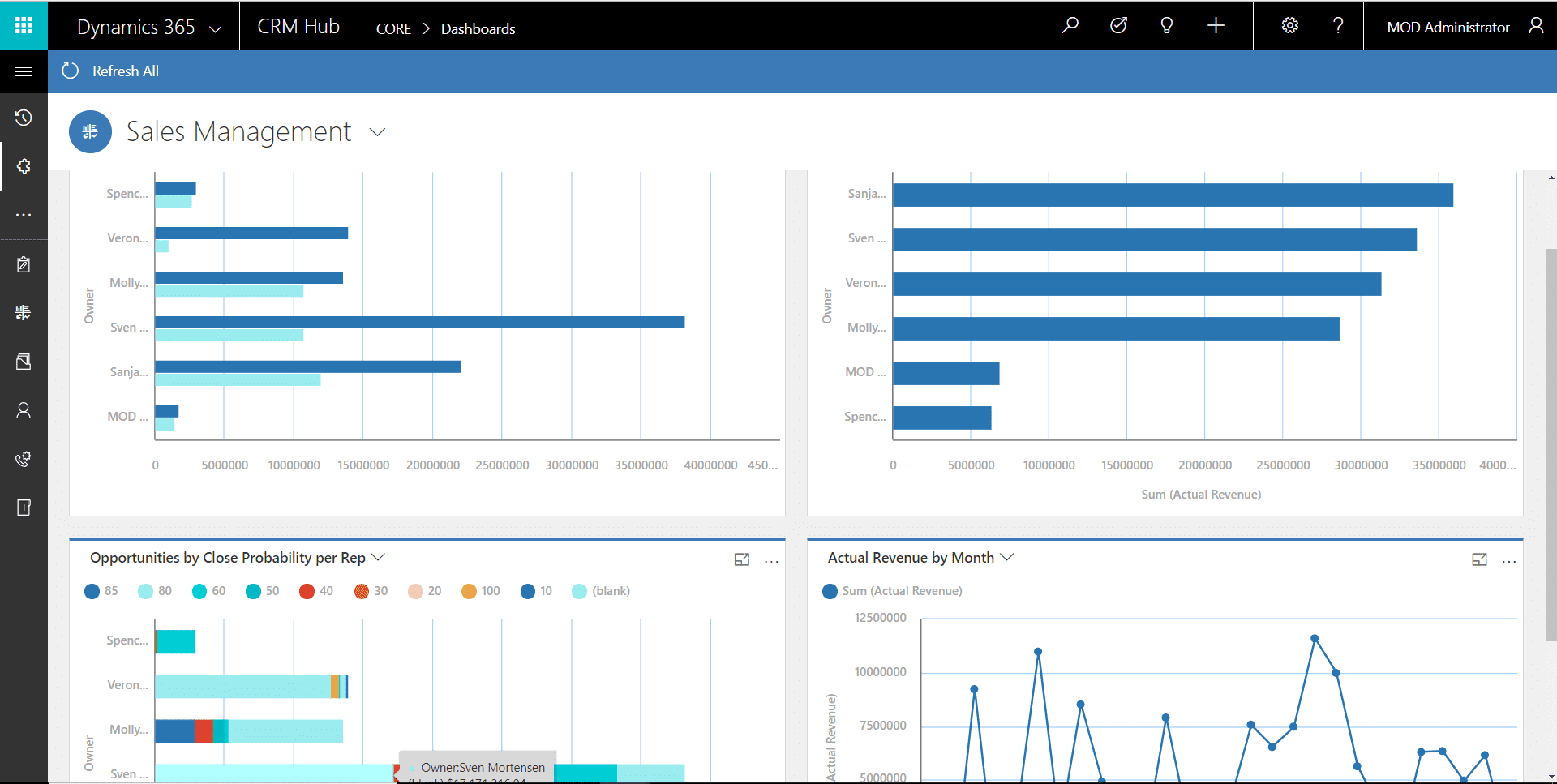

Microsoft Dynamics 365

Microsoft Dynamics 365 is a powerful enterprise resource planning (ERP) software that can be used in the chemicals industry to manage and streamline various business processes. Here are some ways in which Dynamics 365 can be used in the chemicals industry:

-

Batch and lot management: The chemicals industry often deals with complex batch and lot management requirements. Dynamics 365 provides robust batch and lot tracking capabilities to help manage and track inventory, production, and quality control processes.

-

Inventory management: Dynamics 365 allows for real-time inventory tracking and management, which is critical for the chemicals industry. It enables you to manage inventory levels, set reorder points, and automatically generate purchase orders.

-

Quality control: Dynamics 365 provides comprehensive quality control features to ensure that chemical products meet the required specifications and regulatory compliance. It enables you to set up quality tests, record test results, and initiate corrective actions if required.

-

Supply chain management: Dynamics 365 can be used to manage the entire supply chain from procurement to production and delivery. It provides end-to-end visibility into the supply chain, allowing you to optimize processes and reduce lead times.

-

Regulatory compliance: The chemicals industry is subject to a range of regulations, including safety, environmental, and transportation regulations. Dynamics 365 can help you comply with these regulations by providing compliance management tools and automating compliance processes.

-

Financial management: Dynamics 365 includes robust financial management features to help manage accounts receivable, accounts payable, general ledger, and financial reporting. This is critical for the chemicals industry, which often deals with complex financial transactions.

Acumatica is a cloud-based ERP (Enterprise Resource Planning) software that can be used as a chemical ERP to manage and optimize the operations of chemical companies. Here are some ways Acumatica can be used:

-

Inventory Management: Acumatica can be used to track the inventory of chemicals, including raw materials, intermediates, and finished products. This can help ensure that the correct quantities of chemicals are available at all times, reducing the risk of stockouts and overstocking.

-

Quality Control: Acumatica can be used to monitor and manage the quality of chemicals. This can include tracking the quality of raw materials, intermediates, and finished products, as well as ensuring that all chemicals meet regulatory requirements.

-

Cost Management: Acumatica can be used to track the costs associated with the production of chemicals. This can include tracking the cost of raw materials, labor, and overhead, as well as analyzing the profitability of different products.

-

Production Planning and Scheduling: Acumatica can be used to plan and schedule the production of chemicals. This can help ensure that production is optimized to meet customer demand while minimizing waste and reducing costs.

-

Regulatory Compliance: Acumatica can be used to ensure that chemical companies are compliant with regulatory requirements. This can include tracking the use of hazardous materials, managing safety data sheets (SDS), and complying with environmental regulations.

-

Sales and Distribution: Acumatica can be used to manage the sales and distribution of chemicals. This can include managing customer orders, invoicing, and shipping, as well as providing customers with access to product information and SDS.

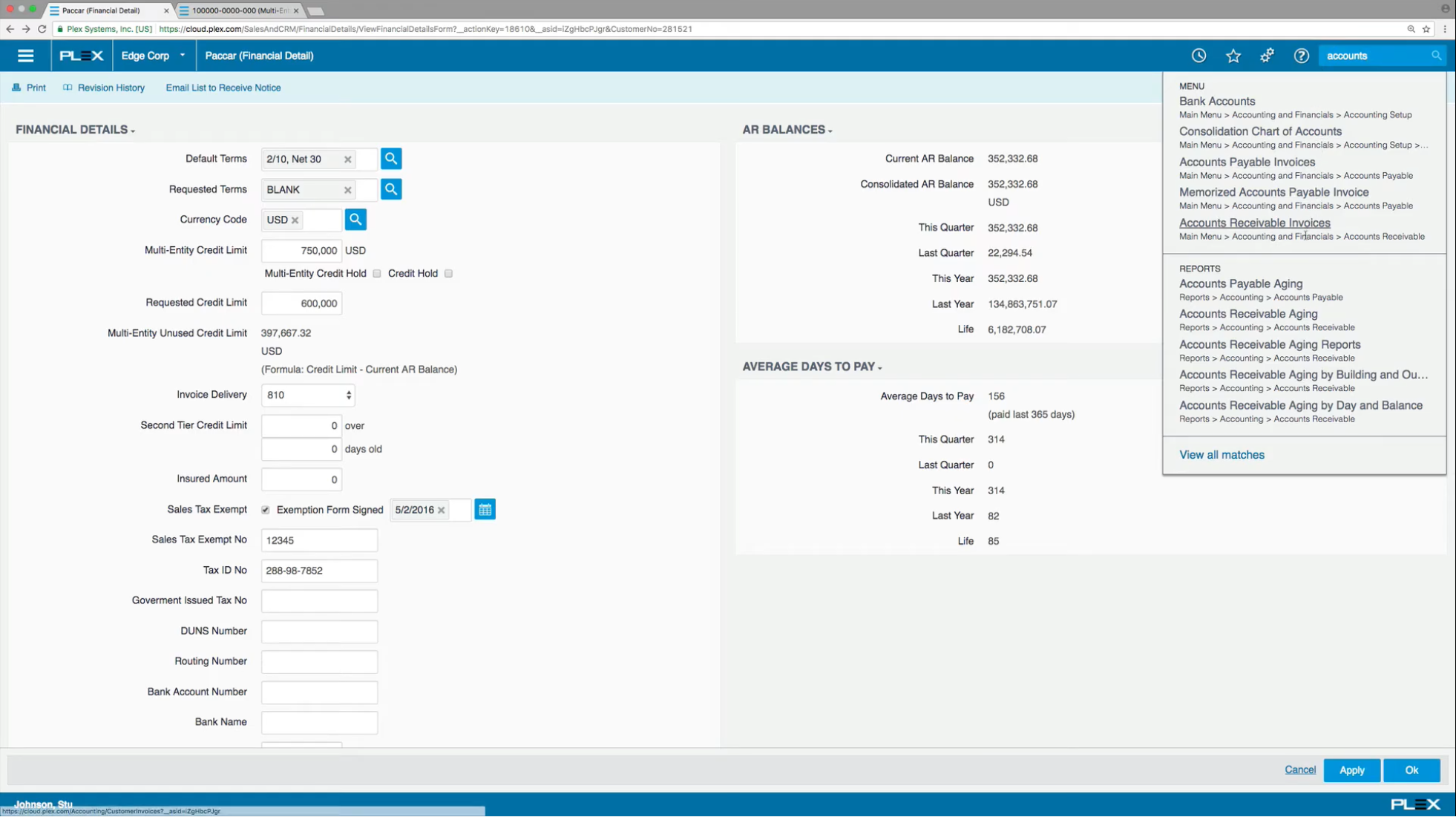

Plex Manufacturing Cloud

Plex Manufacturing Cloud is a cloud-based Enterprise Resource Planning (ERP) software solution that provides businesses with a comprehensive set of tools to manage their operations, including production planning, inventory management, quality control, supply chain management, and financials.

For chemical manufacturing companies, Plex Manufacturing Cloud can be used as an effective Chemicals ERP to manage their complex production processes, regulatory compliance, and supply chain operations. Here are some ways in which Plex Manufacturing Cloud can be used as a Chemicals ERP:

-

-

Recipe Management: Plex Manufacturing Cloud provides robust recipe management capabilities that enable chemical manufacturers to create and manage complex formulations, calculate costs, and maintain detailed records of ingredients, specifications, and regulatory compliance.

-

Production Planning: The software's production planning capabilities allow manufacturers to plan and schedule production runs based on demand forecasts, production capacity, and inventory levels. The system can automatically adjust production schedules based on changes in demand or inventory levels, ensuring optimal use of resources.

-

Quality Control: Plex Manufacturing Cloud has built-in quality control features that allow manufacturers to track and manage quality control data, including test results, compliance documentation, and audit records. The system can also generate alerts and notifications when quality standards are not met, enabling manufacturers to take corrective actions in a timely manner.

-

Supply Chain Management: Chemical manufacturers can use Plex Manufacturing Cloud to manage their supply chain operations, including procurement, inventory management, and supplier relationships. The system provides real-time visibility into inventory levels, delivery times, and supplier performance, allowing manufacturers to optimize their supply chain operations and reduce costs.

-

Regulatory Compliance: Compliance with regulations such as REACH, GHS, and FDA can be a complex and time-consuming process. Plex Manufacturing Cloud provides built-in regulatory compliance features that enable chemical manufacturers to track and manage compliance documentation, automate compliance reporting, and ensure adherence to regulatory standards.

-

What is the best ERP for manufacturing in 2021?

We review the best ERP software for manufacturing? We compare and rank the best ERP software for manufacturers in 2021 including SAP Business One, Netsuite, Infor & more.

ERP Requirements Gathering (RFI, RFP) Template Excel

Start your ERP evaluation process with our RFI & RFP Excel template for the engineering industry.

ERP Project Budget Calculator Template

Calculate the costs of your manufacturing ERP project with our prebuilt budget calculator.

Top Food ERP Modules & Functionality

The top ERP software for chemicals manufacturers can include a variety of modules and functionalities that allow manufacturing companies to scale and be more efficient. We review some of the key functionality for the best food and beverage manufacturing ERP software below:

Accounting and Financials

The best ERP for manufacturing has to include accounting and financials capabilities across multiple geographies and business units.

Purchasing

Purchasing needs to be controlled and the best ERP software for manufacturing allows you to do just this.

Production

Plan your supply chain and manage your manufacturing process in one wholistic ERP system including bill of materials management and kits.

Engineering Management

Manufacturing ERP software needs tight engineering capabilities to quickly iterate products whilst maintaining efficiencies.

Inventory Management

ERP systems for manufacturing allow for real time insights into inventory levels across your organization to drive efficiency.

Asset Management

Manage business assets with ERP for manufacturing to easily capitalise and monitor your assets.

Reporting and dashboards

Develop a single view of your manufacturing business in order to increase transparency, decision-making and ultimately drive results.

Expenses Management

Automate expenses requisitions and approvals for your sales team or manufacturing within your ERP system.

Customer Service

Customer service is a crucial part of top ERP software for manufacturing. Tie in data across production, sales and more with manufacturing ERP.

Sales management

Track & plan sales pipeline, score leads, prospects and forecast opportunities in real-time across territories, accounts and teams.

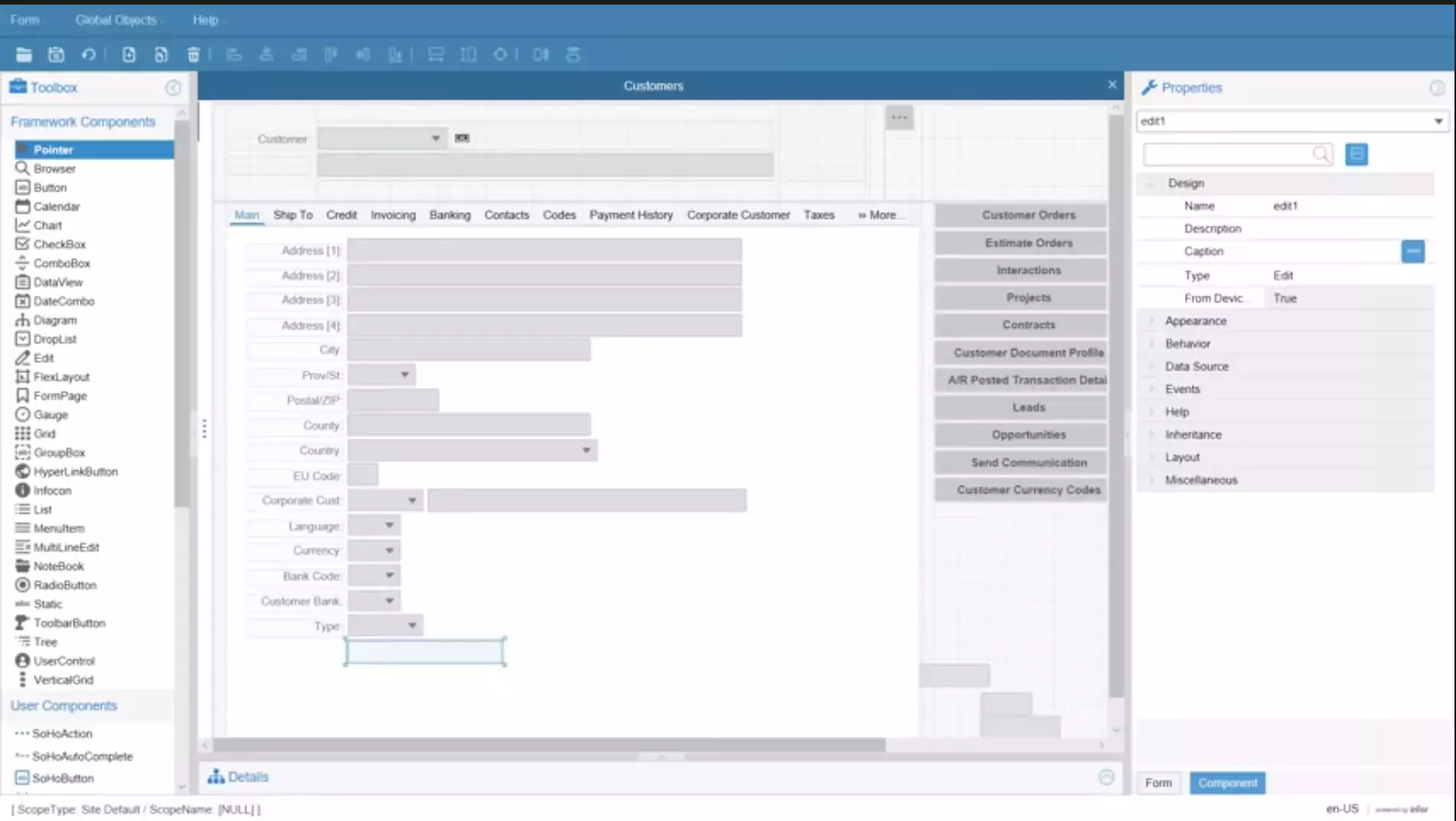

Customisation

Flexible ERP software that's built on an open and extensible foundation, allowing you to choose the features that suit your business needs.

Mobility

Access your ERP data at any time so you're more available to customers and take advantage of unexpected opportunities as they surface.

Development tools

ERP software for the manufacturing industry features all of the tailored solutions an organization needs to design, build and document their projects faster.

Updates and maintenance

Backed by the consistency of market-leading vendors, ERP software regularly updates to ensure an optimal user experience.

Versatile deployments

Connects customers, partners, and employees through real-time digital relationships to improve the way you do business.

Unlimited support

ERP implementation is a longterm strategic partnership and vendors provide free unlimited technical support for clients.

Chemical Industry ERP Guide

When considering ERP software for chemicals, savvy ERP buyers tend to have a lot of questions. Below we answer some of the most frequently asked questions around chemical ERP:

What is Chemical ERP software?

ERP, or enterprise resource planning, is a powerful software solution that has revolutionized the way businesses in the chemical industry operate. This technology offers a comprehensive suite of tools that can help manage everything from production planning and scheduling to supply chain management, financial accounting, and more. With ERP for chemicals, companies can streamline processes, optimize resources, and make better-informed decisions based on real-time data. This results in increased efficiency, reduced costs, and improved profitability. Whether you are a small chemical manufacturer or a large multinational corporation, implementing an ERP solution can give you a significant competitive advantage in today's rapidly evolving marketplace.

Which chemical companies use ERP software?

In today's fast-paced business world, chemical companies must rely on advanced technology to manage their complex operations. Many chemical companies have adopted ERP software to streamline their business processes, improve efficiency, and gain a competitive advantage. Some of the leading chemical companies that use ERP software include BASF, Dow Chemical, DuPont, and Bayer. These companies have invested in ERP software to manage their supply chain, production, inventory, and financials. By using ERP software, chemical companies can make data-driven decisions, reduce costs, and improve customer satisfaction. Whether your company is a small start-up or a large multinational corporation, adopting ERP software can help you achieve your business goals and stay ahead of the competition.

What is the best ERP software for chemicals?

As the chemicals industry continues to evolve, it has become increasingly vital for businesses to have powerful enterprise resource planning (ERP) software that can keep up with their changing needs. Finding the right ERP software can be a daunting task, but there are a few key features that businesses in the chemicals industry should consider when evaluating their options. These might include real-time inventory tracking, advanced analytics capabilities, and robust supply chain management tools. Ultimately, the best ERP software for chemicals will depend on the specific needs of your business, but by carefully evaluating your options and selecting a solution that meets your unique requirements, you can take your operations to the next level and drive sustainable growth for years to come.

What is the best manufacturing ERP software for chemicals?

What are the benefits of ERP software for chemicals?

Start Your ERP Journey With ERP Research

We help manufacturing firms to prepare for ERP change by guiding them through each stage of the process:

-

Build An ERP Business Case 2-3 weeksA solid business case is a foundation you need if you are going to persuade your organization to consider enterprise resource planning (ERP) implementation. Download Business Case Template

-

Compare ERP Vendors 2-3 weeksIt’s critical to understand which ERP vendor is right for your business. Before you decide on the vendor for your company, take a look at our solution pages to find out which vendor would be best. Compare ERP Vendors

-

Get Pricing Estimates 1-2 weeksOur exclusive process removes all the salesmen from the equation and gets you real pricing estimates from every qualified vendor. Contact Us For Pricing

-

Organize A Solution Demo 1-2 weeksDuring a demo, you will learn about how large corporations are making use of ERP software and how they are improving their business practices. Book A Demo

-

Build ERP Requirements 3-4 weeksIf you're looking to buy an Enterprise Resource Planning (ERP) system or upgrade your internal systems you will need a clear definition of all the functions, features and capabilities that you expect. You can approach this challenge by building what's called an ERP requirements document. Download ERP Requirements Template

-

Shortlist 4-8 Vendors 1 weekOne of the most important phases in the ERP project lifecycle is selecting the right software vendor. Ideally, you should shortlist 4-8 vendors - based on their credentials and your requirements. Contact Us To Shortlist Vendors

.png?width=278&name=sap-s-4hana-logo%20(2).png)