SAP S/4 HANA Warehouse Management / EWM Overview

Learn about SAP S/4 HANA WMS / EWM module with our independent analysis of the features and capabilities of S/4 HANA warehouse management module.

SAP S/4 HANA Warehouse Management Module Guide

What are the features and capabilities of S/4 HANA Warehouse Management?

SAP S/4HANA Warehouse Management (WM) is an integral part of the SAP S/4HANA Enterprise Management system, designed to optimize and streamline warehouse and distribution center operations. The module can be used as a standalone solution or integrated with SAP Extended Warehouse Management (EWM) for more advanced warehouse management capabilities. Key features and capabilities of the S/4HANA Warehouse Management module include:

- Warehouse Structure and Organization:

- The module allows you to define and manage a hierarchical warehouse structure, including storage types (e.g., high rack storage, bulk storage), storage sections, and storage bins.

- You can also configure specific storage bin attributes, such as maximum capacity, dimensions, and storage conditions, enabling efficient space utilization and organization.

- The system supports the automatic determination of putaway and picking strategies based on storage type, material characteristics, and other factors, optimizing material placement and retrieval.

- Inbound Processes:

- S/4HANA WM manages the entire inbound process, from goods receipt and putaway to quality inspection and stock posting.

- The module supports various goods receipt scenarios, such as inbound delivery, production order confirmation, and stock transport orders.

- You can configure putaway strategies based on factors like storage type, material characteristics, or storage conditions, ensuring efficient and accurate storage of materials in the warehouse.

- Outbound Processes:

- The module streamlines outbound processes like order picking, packing, and goods issue, optimizing order fulfillment and ensuring timely delivery to customers.

- S/4HANA WM supports various picking strategies, such as first-in, first-out (FIFO), last-in, first-out (LIFO), and wave picking, enabling you to choose the most suitable approach for your business.

- You can also configure packing rules, such as packing material and container types, to ensure efficient and compliant shipment preparation.

- Internal Warehouse Movements:

- The system facilitates internal warehouse movements, such as stock transfers, replenishments, and reorganization, ensuring optimal stock placement and efficient warehouse operations.

- You can configure automatic replenishment strategies based on factors like minimum and maximum stock levels, ensuring that pick locations are always sufficiently stocked.

- The module also supports ad hoc stock transfers, allowing you to quickly move materials within the warehouse as needed.

- Warehouse Monitoring and Control:

- S/4HANA WM provides real-time visibility into warehouse operations, stock levels, and material movements, enabling you to proactively monitor and control warehouse activities.

- The system offers various monitoring tools, such as warehouse activity monitors and alert monitors, that help you detect and resolve potential issues before they escalate.

- You can also define exception handling rules and workflows, ensuring that any deviations from standard processes are appropriately managed.

- Batch and Serial Number Management:

- The module supports batch and serial number management, allowing you to accurately track and trace materials throughout the warehouse and supply chain.

- You can maintain batch-specific attributes, such as manufacturing date, expiration date, and quality specifications, ensuring product quality and compliance with regulatory requirements.

- Serial number management enables you to track individual items from production to sales or service, providing full traceability and supporting warranty and service management processes.

- Physical Inventory and Cycle Counting:

- S/4HANA WM enables you to perform physical inventory and cycle counting procedures to maintain inventory accuracy and ensure compliance with auditing and regulatory requirements.

- The system supports various physical inventory methods, such as periodic inventory, continuous inventory, and ad hoc inventory counting.

- You can create and manage inventory counting documents, record count results, and perform inventory adjustments based on the count results, ensuring accurate stock representation in the system.

- Integration with Material Management and Production Planning:

- S/4HANA WM is closely integrated with other SAP modules, such as Material Management (MM) and Production Planning (PP), providing a seamless connection between warehouse operations and other supply chain processes.

- This integration enables end-to-end visibility and control over your supply chain, helping you optimize processes like procurement, production planning, and order fulfillment.

- Warehouse Resource Management:

- The module offers resource management capabilities that help optimize the utilization of resources, such as labor, forklifts, and AGVs, in the warehouse.

- S/4HANA WM allows you to manage labor resources by defining work centers, resource capacities, and work schedules, helping you allocate tasks efficiently and balance workloads.

- The system also supports the integration and management of material handling equipment, such as forklifts and AGVs, streamlining warehouse movements and reducing manual handling requirements.

- Advanced Picking Strategies:

- S/4HANA WM supports various advanced picking strategies, including wave picking, cluster picking, and two-step picking, enabling businesses to optimize their order picking processes.

- Wave picking allows you to group multiple orders into a single picking run, reducing travel time and increasing picking efficiency.

- Cluster picking enables the simultaneous picking of multiple orders or order lines, while two-step picking separates the picking and packing processes for improved accuracy and efficiency.

- Warehouse Analytics and Reporting:

- The module provides a range of pre-built warehouse analytics, reports, and key performance indicators (KPIs) that enable businesses to monitor warehouse performance, identify trends, and make data-driven decisions for continuous improvement.

- You can leverage SAP's embedded analytics tools to create custom reports and dashboards or integrate with third-party business intelligence (BI) solutions for advanced analytics capabilities.

- Real-time analytics helps you identify potential bottlenecks, inefficiencies, and improvement opportunities, enabling proactive warehouse management and optimization.

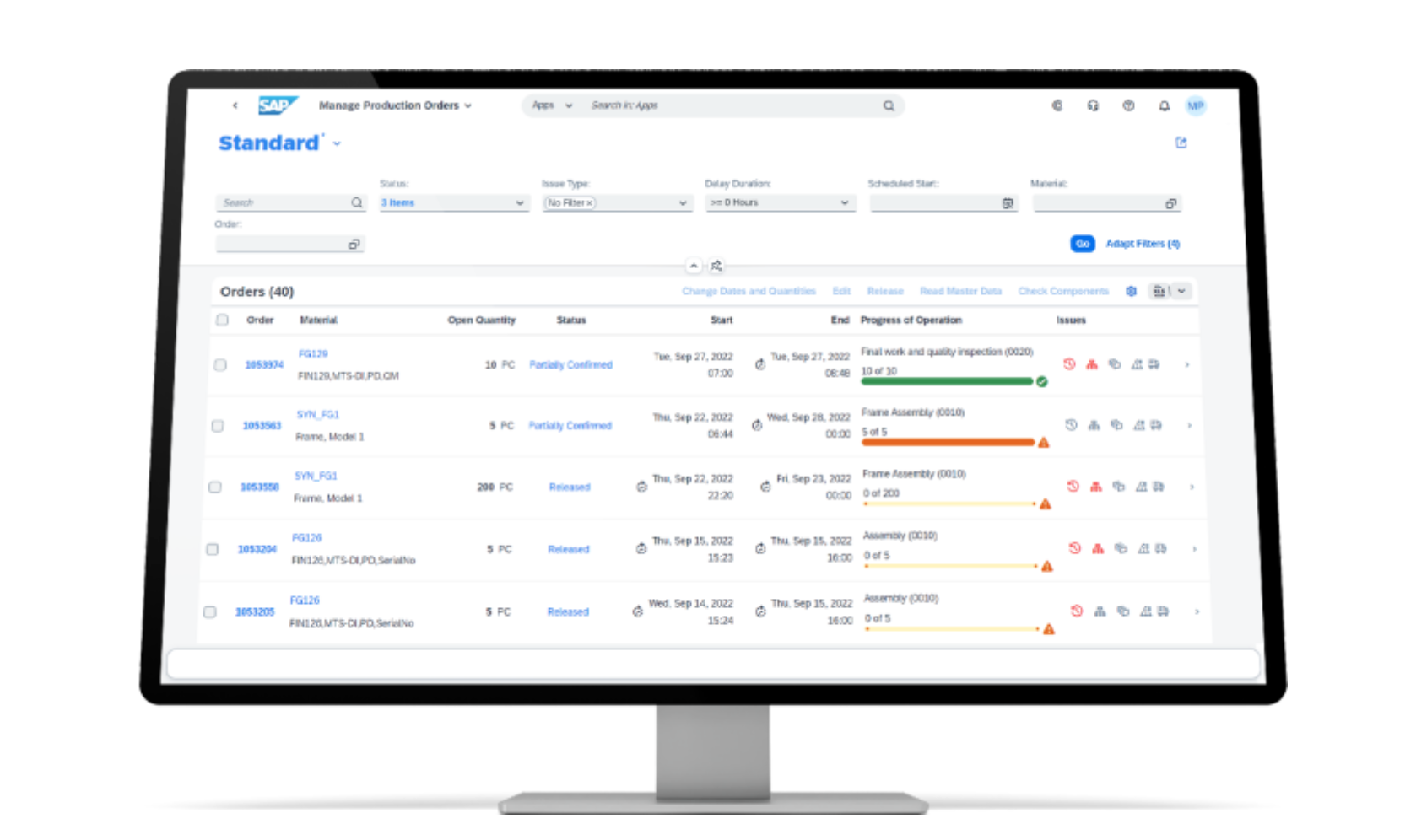

- Fiori User Interface:

- SAP S/4HANA Warehouse Management leverages the modern and user-friendly SAP Fiori interface, allowing users to access warehouse information and perform tasks efficiently through intuitive navigation and personalized dashboards.

- Fiori provides role-based access and workflows, ensuring that users have access to relevant information and tasks based on their job responsibilities.

- The interface's ease of use and adaptability improve user productivity and reduce the learning curve for new users.

What are the features of SAP EWM and how is it different to standard SAP WM?

SAP Extended Warehouse Management (EWM) is an advanced warehouse management solution designed to optimize complex and high-volume warehouse operations. While SAP Warehouse Management (WM) is a robust module for managing warehouse processes, EWM offers additional features and capabilities to handle more sophisticated and large-scale warehouses. Here are some key features of SAP EWM and the differences compared to standard SAP WM:

- Decentralized Architecture:

- EWM can be deployed as a standalone, decentralized solution or as an embedded application within SAP S/4HANA.

- This decentralized architecture allows EWM to manage multiple warehouses independently, providing greater flexibility, scalability, and performance compared to SAP WM.

- Enhanced Warehouse Structure:

- EWM offers a more granular and flexible warehouse structure compared to SAP WM, including storage types, storage sections, storage bins, and activity areas.

- This advanced structure enables more efficient space utilization, material handling, and process optimization in large and complex warehouses.

- Advanced Inbound and Outbound Processes:

- EWM supports advanced inbound and outbound processes, such as value-added services (VAS), kitting, cross-docking, and yard management.

- These advanced capabilities enable more efficient goods receipt, putaway, order picking, packing, and goods issue processes compared to SAP WM.

- Labor Management:

- EWM includes labor management functionality, allowing you to manage workforce planning, productivity, and performance in the warehouse.

- This feature helps optimize labor utilization, reduce labor costs, and improve overall warehouse efficiency compared to SAP WM, which lacks built-in labor management capabilities.

- Slotting and Rearrangement:

- EWM offers slotting and rearrangement functionality, which helps optimize material storage and handling based on factors like demand patterns, storage requirements, and material handling equipment.

- This feature allows you to continually optimize warehouse operations and reduce picking and putaway times, which is not available in standard SAP WM.

- Warehouse Monitoring and Analytics:

- EWM provides advanced warehouse monitoring and analytics tools, such as Warehouse Management Monitor (WMM), Warehouse Cockpit, and Easy Graphics Framework (EGF).

- These tools offer real-time visibility into warehouse processes, KPIs, and exceptions, enabling better decision-making and process optimization compared to SAP WM.

- Task and Resource Management:

- EWM includes advanced task and resource management capabilities, such as wave and replenishment management, resource optimization, and material flow system (MFS) integration.

- These features help optimize material handling, reduce manual intervention, and improve warehouse throughput compared to SAP WM.

- Enhanced Integration:

- EWM is closely integrated with other SAP modules and solutions, such as SAP S/4HANA, SAP Transportation Management (TM), and SAP Global Track and Trace (GTT).

- This integration allows for seamless end-to-end supply chain visibility and management, compared to SAP WM, which has limited integration capabilities with these solutions.

In summary, SAP EWM is an advanced warehouse management solution that offers additional features and capabilities compared to standard SAP WM. EWM is designed to handle complex and high-volume warehouse operations, providing advanced warehouse structure, labor management, task and resource management, and enhanced integration with other SAP solutions. While SAP WM is suitable for smaller warehouses and less complex operations, EWM is a more powerful and scalable solution for larger and more sophisticated warehouse environments.

Which companies use SAP S/4 HANA WMS functionality?

SAP S/4HANA Warehouse Management System (WMS) and Extended Warehouse Management (EWM) are widely used by companies across various industries to optimize and manage their warehouse operations. Here are a few examples of companies that have implemented SAP S/4HANA WMS and EWM functionality:

-

Unilever: The global consumer goods company uses SAP EWM to streamline its warehouse and distribution operations, improving efficiency, inventory accuracy, and customer service.

-

Johnson & Johnson: The multinational healthcare and pharmaceutical company leverages SAP EWM to manage its complex warehouse operations, ensuring accurate inventory management, efficient order processing, and seamless integration with other supply chain processes.

-

Coca-Cola: The world's leading beverage company uses SAP EWM to optimize its warehouse and distribution operations, enhancing inventory visibility, reducing costs, and improving overall supply chain efficiency.

-

Bosch: The multinational engineering and technology company implemented SAP EWM to manage its warehouse operations, enabling better space utilization, efficient material handling, and seamless integration with SAP S/4HANA.

-

BMW: The luxury automobile manufacturer uses SAP S/4HANA WMS to manage its warehouse operations, enhancing its production planning, logistics, and overall operational efficiency.

-

Airbus: The European multinational aerospace corporation has implemented SAP EWM to streamline its warehouse processes, enabling better visibility, efficiency, and decision-making across its global supply chain.

SAP S/4 HANA Cloud Solution & Pricing Guide

Read our guide to S/4 HANA including modules and functionality, pricing, implementation, hidden costs and more.

ERP Implementation Methodology

If you're considering implementing ERP software, then download our free detailed guide to ERP implementation methodology.

Our guide will help you prepare your team for every step of ERP implementation from design to build. testing, go-live and more.

SAP S/4 HANA Pricing

SAP S/4 HANA pricing is licensed on a subscription basis which is typically paid annually.

Licensing is dependent on the amount of users, their level or responsibilities within the system, advanced modules and third party extensions you require.

Let us know how many users you need and we'll be in touch to provide a quick, hassle free SAP S/4 HANA cost estimate.

Start Your SAP S/4 HANA Evaluation

ERP Requirements Document

Compare and evaluate SAP Business One (B1) as well as other ERP solutions with our free ERP requirements document checklist. Use our free template to build your own ERP functional and non-functional requirement.

ERP Vendor Selection Criteria Checklist

Start your ERP evaluation process faster by downloading our ERP Software Vendor Selection Criteria Checklist.

Compare ERP Systems

Get 1-1 advice with an ERP Research specialist to help you compare Infor CloudSuite Industrial (Syteline) and select the best ERP solution for your business.